YOUR EXPERT FOR PACKAGING MACHINES

Packaging is subject to the pressure of logistical challenges, promotionally effective design, and ease of handling. With our packaging machines and system modules for automated end-of-line packaging, we are able to offer you high-quality, state-of-the-art solutions with great potential for rationalization and cost optimization.

You can send you e-mail enquiry directly to one of our ETT-Experts or call +49 151 462 59 161

A reliable case or tray forming process – even for high speed requirements and customer-specific case formats.

Before the product can be packed, the case has to be produced in the first step. Both the tray and the case former automatically pick up the blanks from a magazine, unfold them, seal the bottom flaps and present the finished cases to the downstream module.

Fast, reliable and flexible erecting of folding cases including sealing of bottom flaps.

Thanks to its tried and tested technology, the case former ensures fast, automatic production of cardboard cases while covering a vast range of formats. The bottom flaps can be sealed with hot glue or self-adhesive tape before the case is supplied to the down-stream equipment.

Our tray former unfolds your blanks of various sizes and glues the formed tray quickly and reliably.

Deliberately designed to achieve a compact, clearly arranged and easily accessible layout, the tray former can either be used a stand-alone unit or integrated into a complete line. Even unusual and special tray types such as trays with stacking lugs, reinforced corners or octogonal trays can be produced quickly and reliably with this tray former. Size changeovers are performed with only a few steps.

Thanks to its rugged welded frame and the integration of custom-tailored collating units and gripper systems as well as customised conveyor equipment, this conventional packaging machine offers numerous possibilities for use – it can handle almost everything!

Our intermittently operating wraparound machine is designed to cover a speed range of up to 30 cases per minute. This packaging machine is suitable for both full wrap packaging and other variants such as trays with or without covers. Thanks to different types of collating units, a wide variety of products can be packed lying flat or standing upright, grouped or individually.

Our case sealers ensure safe transport of your products.

As the last station in a packaging line, the case sealer ensures that the packed case is securely sealed to protect your product during transport. We offer different sealer models to handle even special case types, e. g. with short, overlapping or single top flaps.

As one of the final modules the case sealer is a must in every end-of-line packaging system.

Depending on the case size and cardboard quality, up to 20 cases per minute can be sealed with tape, or up to 60 case per minute with hot glue. When the case passes through the sealer, its front top flap is turned inwards while the rear flap is folded down by a starwheel. In the next step, the outer top flaps are closed by controlled folding strips and sealed.

Designed for cases with just one flap, the single flap closer achieves a maximum speed of 30 cases per minute* (depending on the case design). The flap can be positioned either on the long side or front of the case, depending on the specific application. The packaging machine design is adapted to the required size range.

The lidder places a lid on the filled case to prepare it for dispatch to the retail trade. Trays or similar case types are thus securely protected against damage during transport. In addition, they can be stacked thanks to the lid attached and used as shelf-ready packaging at your customer’s point of sale.

The conventional lidder can both insert U-lids into cases/trays and form four-sided trays around the filled case /tray. To form cover trays, the machine is fitted with a separate hot glue application unit. This module can be integrated into a new all-in-one packing system but is also suitable for implementation into your existing line.

Fast and versatile lidding – inline via Line Tracking.

This robot-based lidder can produce both U-lids and cover trays. The key benefit of this machine is its ability to move freely in space: it can place the lids onto the passing cases/trays on the running conveyor (Line Tracking) and also perform even complex inserting processes.

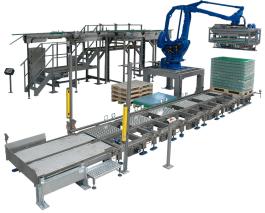

Robots for automatic palletisation.

Automatic palletisation of heavy goods makes end-of-line packaging so much easier. We do not only offer compact palletising cells but also powerful multi-station or central palletising systems for integration behind your packaging line. By using customised vacuum suction or gripper systems we ensure the safe and fast palletisation of your products.

Safe unloading and loading of pallets:

ETT’s palletisers are powerful, versatile and efficient. They ensure gentle and careful handling of your goods as well as time- and space-saving preparation of the finished packaging for transport. As the first element of end-of-line packaging, the depalletisers unload the containers to be filled from the pallet for transfer to the filling process.

When the primary packaging is delivered on a pallet, it needs to be depalletised for to the filling process. We offer the perfect solution for the orderly depalletisation of theses products. Depending on the product properties and speed requirements, the products are unloaded either row by row or layer by layer, and can be placed on a layer table or directly onto the supply conveyor of the filling system. This system is suitable not only for empty packages but also for filled containers made of plastic, glass or aluminium.